Let's Talk

The bill of materials, or BOM, is the description of the components needed to build a product. For example, let's say we had to build a table. The BOM would indicate you need a tabletop, four legs, and some screws to assemble the table. Since each individual component can also have its own bill of materials, there are what we call bill of materials levels. Each with its own set of sub-components. Similarly, a sub-component can also have its own bill of materials, creating multiple levels of bill of materials. This feature is very important, but it's a functionality that some ERP software doesn't handle properly. However, this feature is included in Odoo ERP software, and you can manage as many different levels as needed.

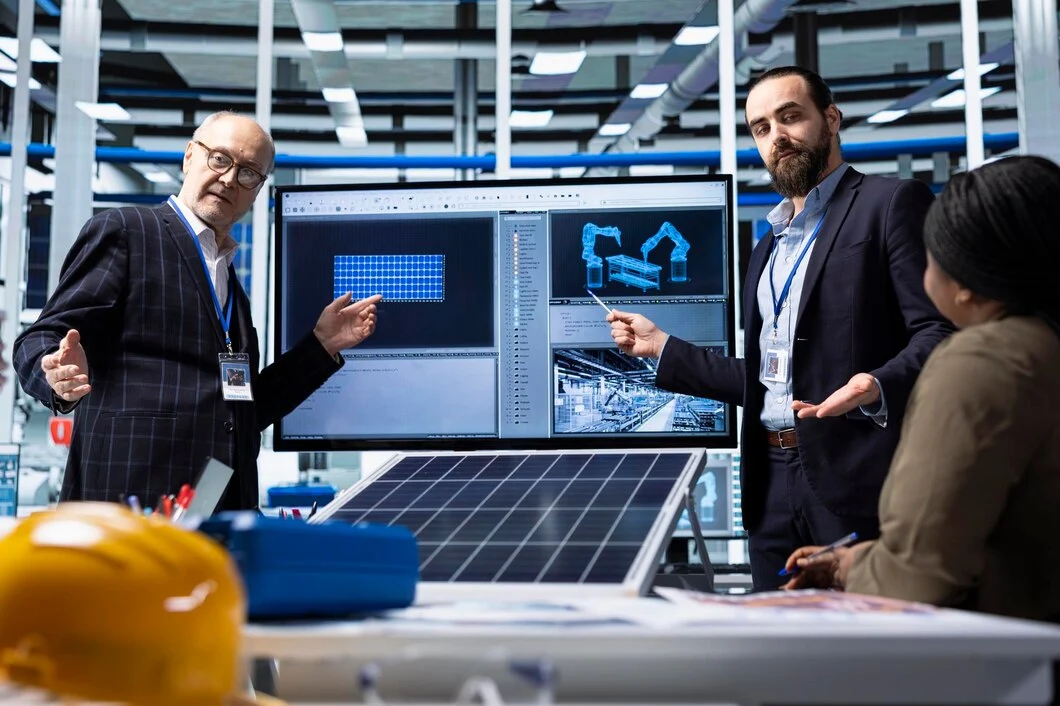

Work orders are documents provided to the manufacturing workshop as signals to produce a certain quantity of a specific product. The work order includes your bill of materials and routing. In other words, it will provide the materials and assembly processes for a product. The system will create an individual work order for each operation and their respective work centers in your ERP. So, to go back to our table example, there will be one manufacturing order and three work orders to assemble the table.

The ERP software Principal Master Production Schedule : The ERP software gives manufacturing facilities the ability to create a master production schedule. A manufacturing center may receive multiple production orders at once, so it's important that everything is created and managed on time. A master schedule allows you to allocate work properly based on the current workload and the capacity of your manufacturing work centers.

Routing is a description, or a roadmap, of the processes that need to be followed to assemble a product. The descriptions are arranged in order based on how a product should be built. For example, with our table, there's a specific process to follow, starting with assembling the table (attaching the tabletop to the legs), then painting the table, followed by varnishing, and finally packaging. Each operation will be handled by a particular work center, and some operations may also be outsourced and performed outside your company. These outsourced tasks can also be managed within the ERP software.

Quality Controls : In addition to routing operations, another step performed is quality assurance. Quality controls can be carried out in several ways:

Employee Monitoring and Performance : Human resource management is a crucial element in any business, especially in manufacturing. ERP systems integrate specific functionalities to track and evaluate employee performance. This includes the ability to monitor employees' activities and progress throughout their assigned tasks. These tracking data enable managers to better understand individual performances, identify areas for improvement, and acknowledge successes.

Workstation : Within a manufacturing ERP system, a workstation represents the location where production operations are carried out by employees. ERP software provides functionalities to manage and organize these workstations effectively. This includes task assignment to employees, scheduling work shifts, monitoring individual and collective performances, as well as managing the resources required for each workstation. Additionally, ERP systems can also integrate time management features, allowing employees to clock their work hours and enabling managers to track and manage worked hours.

Product Traceability : Products can be easily traced back to their original material through product traceability. This is a highly important feature, especially when there is an issue with a finished product. Parts can be traced with a lot number, and all products with that specific component can be marked or recalled. They can be tracked by batch or serial number. A product's serial number is a unique quantity of a product, whereas a lot number is how we reference multiples of the same product.

ERP software enables you to manage alerts and quality controls. By managing quality controls, problem areas can be quickly identified, resolved, and prevented from recurring.

Create invoices, track payments, and optimize payment deadlines to maintain a healthy cash flow. Benefit from an automated solution that streamlines your billing and payment processes in the Manufacturing ERP software.

Analyze trends, evaluate performance, and draw valuable insights from your ERP software to guide your company's growth. Make better decisions through in-depth data analysis and customized reports for the manufacturing sector.

Cultivate strong relationships with your customers and increase sales with a comprehensive and efficient management solution. Track leads, automate sales processes, and personalize your communication to boost your company's revenue in ERP solutions for manufacturing.

Enhance expense report management for the [industry type] sector through the use of an ERP. Track expenses, automate reimbursements, and ensure employee satisfaction.

Keep a close eye on your finances in manufacturing industry ERP sector with an ERP software ensuring your financial and accounting management. Manage cash flows, budgets, and financial reports for effective financial management of your business.

Optimize inventory management and be prepared to meet all demands in the [industry type] sector. Track stock levels, manage supplies, and minimize stockouts to ensure customer satisfaction.

Ensure effective workforce planning by simplifying leave and absence management. Track leave requests, establish flexible policies, and minimize schedule conflicts to maintain high productivity in the manufacturing ERP software.

Plan and track your production in your ERP to optimize supply chain efficiency and ensure product quality. Manage work orders, track production times, and ensure timely delivery to meet the requirements of customers in manufacturing industry ERP.

Simplify the procurement process to reduce costs and optimize operations in the [industry type] sector. Automate workflows, manage suppliers, and optimize purchase contracts to ensure the quality of products and services.

Ensure compliance with the highest quality standards in manufacturing industry ERP. Identify and correct non-conformities, track performance, and guarantee customer satisfaction by delivering superior quality products and services.